Safran relies on CS Group to develop a new fluid mechanics simulation chain, based on ProLB software, for the development of its new technologies, particularly in propulsion.

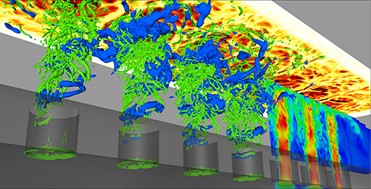

The development of new engine technologies to meet the challenges of decarbonizing aviation requires technological breakthroughs in areas such as thermal management of ultra-high-efficiency engine components, and control of the noise emitted by new “unshrouded” engine architectures. These challenges will have to be tackled within a short timeframe, while keeping engineering costs under control, to enable Safran to offer effective, reliable and competitive breakthrough solutions.

Fluid mechanics simulation is an integral part of Safran’s product design cycle. For several years now, CS Group has been developing ProLB, a Computational Fluid Dynamics (CFD) software package based on an innovative numerical method known as “Boltzmann on Network”, enabling high-fidelity simulations to be carried out in a very short time. CS Group is developing ProLB in partnership with Airbus, Renault, the Laboratoire de Mécanique des Fluides et d’Acoustique (Ecole Centrale de Lyon), the Laboratoire de Mécanique, Modélisation et Procédés Propres (Université Aix-Marseille) and the CNRS.

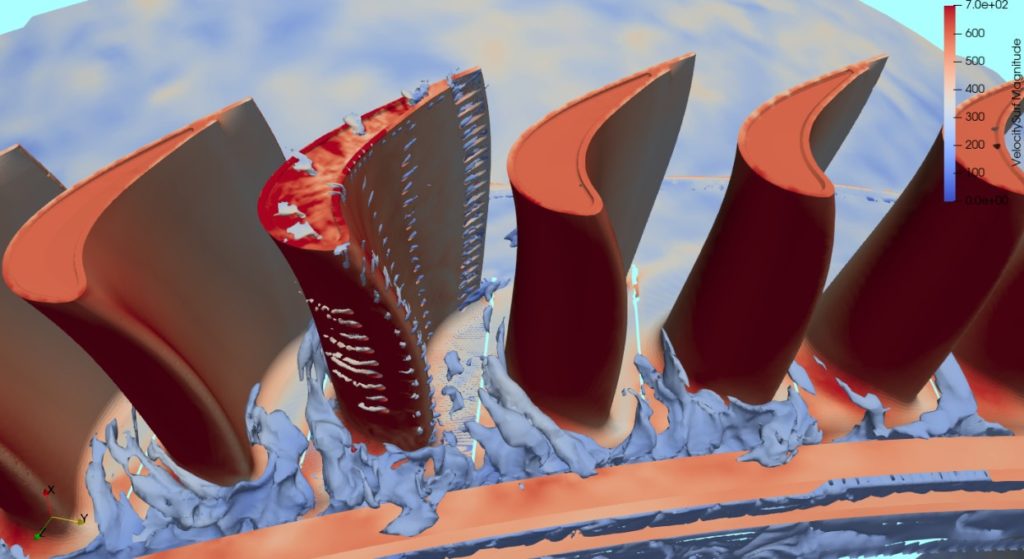

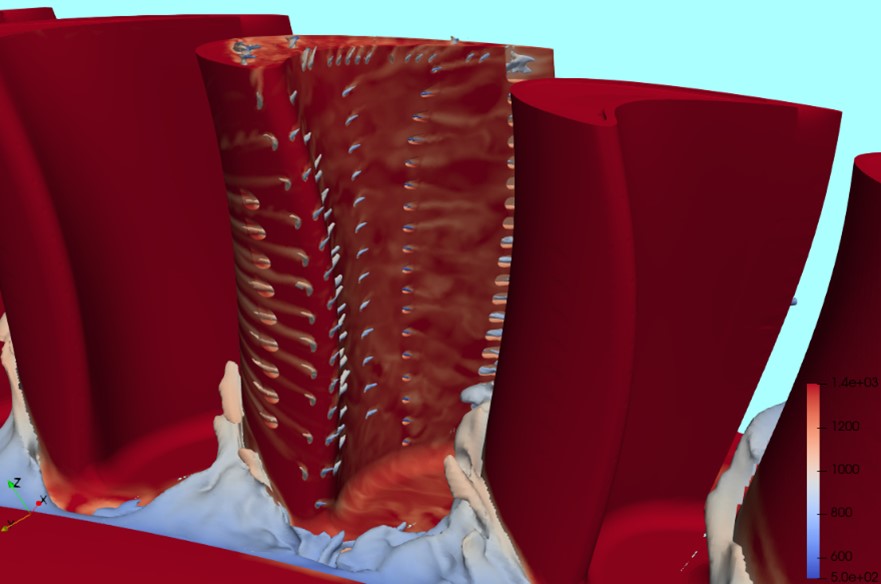

By signing a multi-year agreement with these partners, Safran joins this consortium to rely on this software for some of their critical aerothermal and aeroacoustic simulations. Safran will use ProLB to simulate these complex physics around their actual geometric configurations in a context of massively parallel high-fidelity simulations (i.e. with a high level of accuracy, while benefiting from reasonable computation times): thanks to ProLB, simulations on meshes of several hundred million meshes computed on thousands of processors can be implemented simply and efficiently.

This multi-year commitment is a consolidation of a scientific partnership between Safran and the ProLB consortium initiated several years ago, notably within the framework of theses and an Industrial Chair supported by Safran on the development and validation of ProLB simulations in the field of high-speed flows. Indeed, as Vincent Garnier, Safran Tech Director, points out, “Safran joined the ProLB consortium after several years of evaluating this new CFD numerical method, and after being convinced of the maturity of the ProLB software in terms of industrial implementation. The quality and accuracy of the physical models is our priority, but the ease and speed with which the software can be implemented on our complex cases are also criteria that we appreciated”.

In addition to the physical models and numerical algorithms, CS Group is developing the environment required for industrial use, which has already been put to the test industrially by Renault and Airbus. The massively parallel physical solver is combined with several complementary modules to form a complete simulation chain: ergonomic pre-processing software for simulation data input, an automatic mesh generator for automatic generation of volume meshes around complex geometries, and a set of post-processing tools providing direct access to relevant information for design engineers.

Pierre Lopez, Managing Director of CS Group: “We are delighted that Safran has decided to support the development of our CFD software, which is resolutely innovative in terms of both physics and HPC (High Performance Computing) techniques. But we are also aware of the challenge that this investment by Safran represents: we need to successfully deploy ProLB on Safran applications that push our physical models to their limits”.

👉 For more information on ProLB, visit the dedicated web site and Linkedin